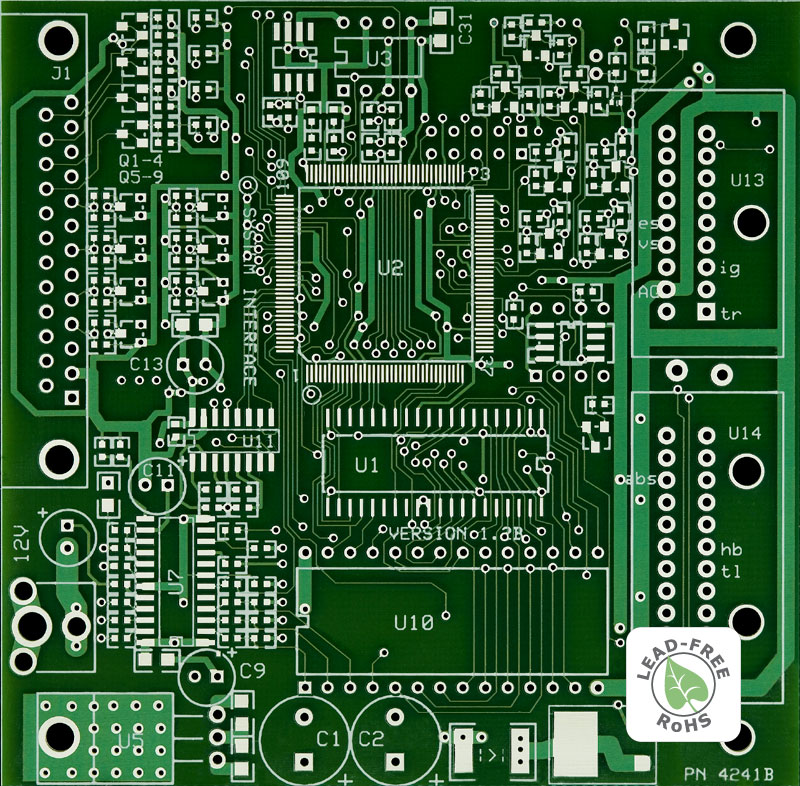

Ảnh sản phẩm thuộc về PNLAB

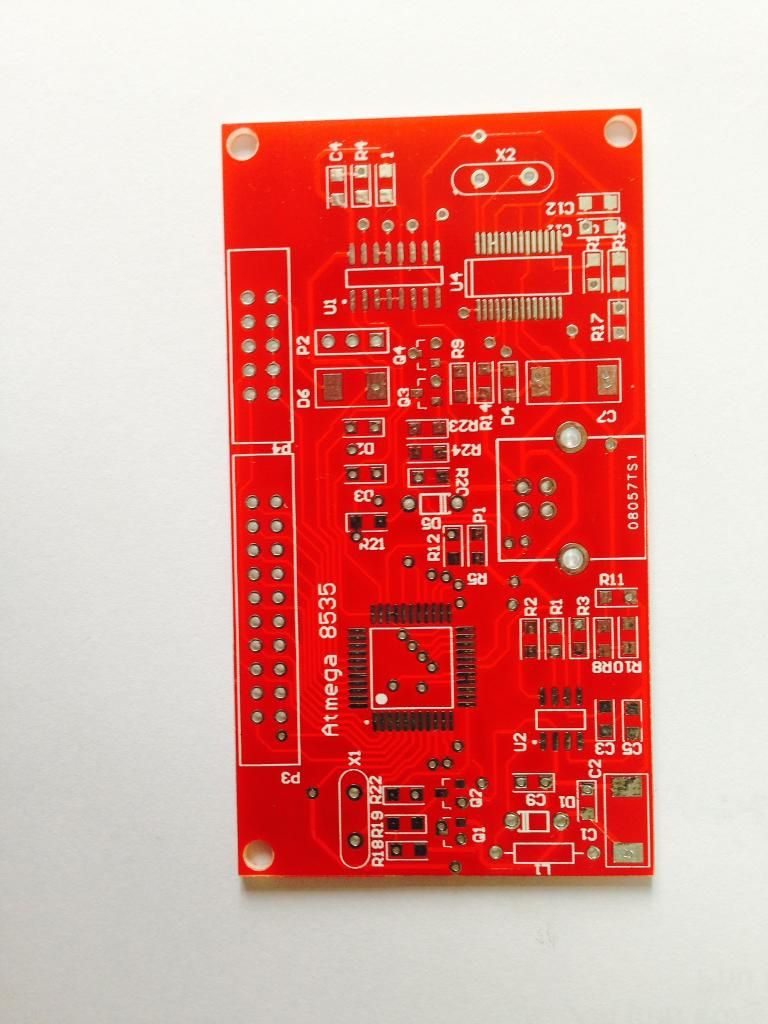

Ảnh sản phẩm thuộc về PNLAB

Thông tin chi tiết sản phẩm |

|||

Tên sản phẩm: |

Mạch in 2 lớp 10x10 cm (10 pcs ) |

||

Giá: |

200.000 |

||

Tình trạng: |

liên hệ |

||

Xuất xứ: |

Chính Hãng |

||

Hãng sản xuất: |

PNLAB |

||

Mã sản phẩm: |

Đang cập nhật |

||

Giá cho 10 pcs

Pnlab cung cấp dịch vụ đặt mạch in 2-6 lớp giá cả hợp lý và cạnh tranh. số lượng đặt tối thiểu 5 tấm. thời gian giao hàng ổn định, chất lượng mạch in tốt. để đặt mạch in quý khách xuất ra file gerber và gửi cho Pnlab ( xem hướng dẫn xuất file Gerber tại đây http://ickeyvn.com/san-pham/717/tao-gerber-file.html ) tới mail : pnlabvietnam@gmail.com . chúng tối sẽ báo giá trong ngày.

Thông số kỹ thuật

| Items | Manufacturing Capabilities | Remarks |

|---|---|---|

| Number of Layers | Single-sided, double-sided, 4-layers, 6-layers | Currently the maximum we can do is 6-layers. |

|

Laminate |

FR-4

|

Currently we only do FR-4 for our orders. |

| Maximum Board Size(Dimension) | 420mm x 1200mm | Most boards are within the size of 420mm x 550mm. |

| Board Size Tolerance(Outline) | ±0.2mm/±0.5mm | ±0.2mm for CNC routing, and ±0.5mm for V-scoring. |

| Board Thickness | 0.4-2.0mm | Currently we offer boards of 0.4/0.6/0.8/1.0/1.2/1.6/2.0mm. |

| Board Thickness Tolerance(t≥1.0mm) | ±10% | Normally “Plus Tolerance” will occur due to PCB processing steps such as electroless copper, solder mask and different types of finish on the pads. |

| Board Thickness Tolerance(t<1.0mm) | ±0.1mm | Normally “Plus Tolerance” will occur due to PCB processing steps such as electroless copper, solder mask and different types of finish on the pads. |

| Minimum Trace | 6mil (0.15mm) | Design larger traces when condition permits. For multi-layer PCBs, the minimum trace on inner-layer should be 0.175mm, and minimum trace on outer layer can still be 0.15mm. |

| Minimum Spacing | 6mil (0.15mm) | Design larger spacing if possible, minimum spacing is 0.15mm. |

| Finished Copper Thickness (Outer Layer) | 35μm/70μm (1 OZ/2 OZ) | Also known as copper weight, 1 OZ equals 35μm, and 2 OZ equals 70μm |

| Finished Copper Thickness(Inner Layer) | 17μm (0.5 OZ) | Our finished copper weight for inner layer is 0.5 OZ which equals 17μm in thickness. |

| Drill Sizes (CNC) | 0.3-6.3mm | Regular drill sizes range from 0.3mm to 6.3mm. Extra charge may apply if larger than 6.3mm. |

| Minimum Annual Ring | 0.153mm (6mil) | Try to use bigger copper pad if possible, and the minimum annual ring is 0.153mm (6mil). |

| Finished Hole Diameter (CNC) | 0.2mm-6.2mm | Due to copper deposition/plating in the hole barrels, the finished hole diameter will be smaller than size of drill bits. |

| Tolerance of Finished Hole Size (CNC) | ±0.08mm | For example, if the drill size is 0.6mm, then the finished holes diameter ranging from 0.52mm to 0.68mm will be considered acceptable. |

| Solder Mask | LPI | Liquid Photo-imageable (LPI) is currently the most accepted solder mask in PCB manufacturing. |

| Minimum Character Width (Legend) | 0.15mm | Characters of less than 0.15mm wide will be too narrow and will be unreadable. |

| Minimum Character Height (Legend) | 0.8mm | Characters of less than 0.8mm high will be too small and will be unreadable. |

| Character Width to Height Ratio (Legend) | 1:5 | The ratio of 1:5 is the best and most popular one in PCB silkscreen legends processing. |

| Minimum Backset (Distance from Copper to Board Edge) | 0.3mm (12mil) / 0.5mm (20mil) | The minimum distance is 0.3mm for CNC routing, while the distance should be 0.5mm if you request V-scoring. |

| Minimum Diameter of Plated Half Holes | 0.6mm | For better connection between boards, we recommend to design this diameter to be at least 0.6mm. |

www.pnlabvn.com

www.pnlabvn.com